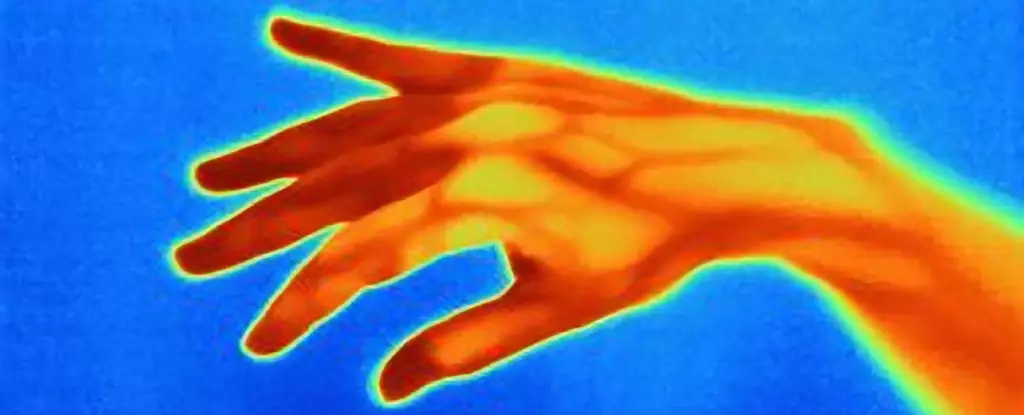

Thermal imaging is a fascinating technology that reveals just how much heat our bodies emit. In fact, our physiology generates enough heat to be compared to the output of 19 matches per square foot per hour. Unfortunately, this heat is typically lost to the environment, presenting a substantial opportunity for energy capture that remains largely untapped. What if we could utilize this waste heat for energy generation? Research has begun to uncover ways to channel this abundant resource efficiently while also adhering to eco-friendly principles.

Body heat is not our only source of wasted energy. Modern industrial processes and transportation systems contribute to significant waste heat, representing an enormous resource that is frequently overlooked. The developing field of waste heat recovery aims to reclaim this excess energy, leading to enhanced operational efficiencies while promoting sustainability. By transforming waste heat into usable energy, industries could drastically reduce their energy consumption and environmental footprint, paving the way for innovative solutions in energy generation.

At the heart of converting waste heat to electricity lies the thermoelectric effect. This scientific principle describes how an electric potential arises when there is a temperature difference, causing electrons to flow from the hotter to the cooler side of a material. However, traditional thermoelectric materials often pose risks due to their toxicity, including elements like cadmium or lead, which can negatively impact both human health and the environment.

Herein lies an exciting development: we can create thermoelectric materials from sustainably sourced wood, a transition from harmful to harmless. Wood’s availability and its historical significance as a material make it a prime candidate for developing eco-friendly energy solutions that are both functional and sustainable.

The research team from the University of Limerick, in collaboration with the University of Valencia, has made significant strides in this area by innovatively using byproducts of the paper industry, particularly lignin, to create energy. Lignin, when treated properly, can be transformed into membranes that efficiently convert low-temperature waste heat—specifically below 200°C—into electricity. This is achieved through the movement of ions within a salt solution that interacts with the lignin membrane, generating an electric potential difference potent enough to harness.

Since about 66 percent of industrial waste heat exists in this low-temperature range, the implications for energy recovery are vast. By turning what was once viewed as waste into a valuable resource, we unlock the potential for substantial energy savings and a decrease in environmental impact across various sectors.

The adoption of lignin-derived technologies can resonate across many industries, particularly in manufacturing, which is traditionally a heavy producer of waste heat. By converting this waste into electricity, manufacturers could significantly lower energy costs, enhance their sustainability practices, and strengthen their commitment to reducing greenhouse gas emissions. Beyond large-scale applications, such technology could also find use in remote areas, allowing for localized energy generation that supports sensors and other electronic devices, ultimately fostering independence from traditional energy sources.

Moreover, the ecological credentials of this technology position it as a viable option for enriching building designs and infrastructure, aiming for maximum energy efficiency in everyday applications.

While harnessing waste heat is a monumental step, the efficiency of energy utilization largely depends on how effectively we can store this captured energy. Supercapacitors serve as a crucial component in this equation, offering rapid charging and discharging solutions necessary for many applications. However, their traditional integration of fossil fuel-derived materials poses sustainability challenges that cannot be overlooked.

Our research highlights the possibility of utilizing lignin-based porous carbon as a renewable electrode material in supercapacitors. This innovative approach not only addresses the pressing need for sustainable materials but also guarantees that energy harvested from waste heat can be stored efficiently. The combination of lignin membranes for energy generation and porous carbon for energy storage offers an eco-friendly answer that eliminates reliance on harmful chemicals.

The quest to harness waste heat through innovative research represents a beacon of hope for achieving sustainability in energy generation. By converting human and industrial waste heat into usable energy and coupling it with green storage solutions, we stand on the precipice of an energy renaissance that could transform our relationship with energy and the environment. Embracing these technologies could not only elevate efficiency standards but also redefine how we view everyday materials as foundations for future sustainable energy solutions.

Leave a Reply